To kick off our AI journey, around 30 managers from member companies came together at Albrecht JUNG GmbH & Co. KG in Schalksmühle on February 4, 2025.

Making AI tangible and seeing and discussing current AI applications live in action in member companies – this is the thematic goal of the AI journey, which will take us to various member companies.

On February 4, 2025, we had the pleasure of visiting JUNG and were given an interesting insight into production and the AI application that is being developed and expanded there in the area of socket production.

After a brief round of introductions, Dirk Wettlaufer, Head of Operations at JUNG and NIRO board member, welcomed the guests and introduced his company. JUNG combines its administration, development center and production in Schalksmühle. High-quality products such as switches and control elements for building technology as well as systems with a timeless design and equipped with smart technology are manufactured there. Socket production traditionally forms the heart of the company.

Dirk Wettlaufer emphasized the importance of the current key technology and the potential that JUNG sees in AI applications. For this reason, an AI focus group was set up at JUNG. A few years ago, our network at JUNG started a lean journey and now we are continuing with AI.

The workshop focused on an AI application that JUNG is using on a fully automated system for the production of sockets. Dr. André Hengstebeck, Head of Industrial Engineering at JUNG, began by presenting the comprehensive data concept that was developed as the basis for the AI application. The level of data analysis should leave “descriptive” and “diagnostic” behind in order to achieve “predictive” and, at best, “prescriptive” results with the use of AI. Only then can errors be reliably predicted, system transparency and performance increased and system performance optimized.

As with all AI applications, success lies in meeting the high data quality requirements. Selecting and defining the required data, ensuring its collection, preparation and modeling are time-consuming processes in preparation in order to provide a basis for the selected AI model.

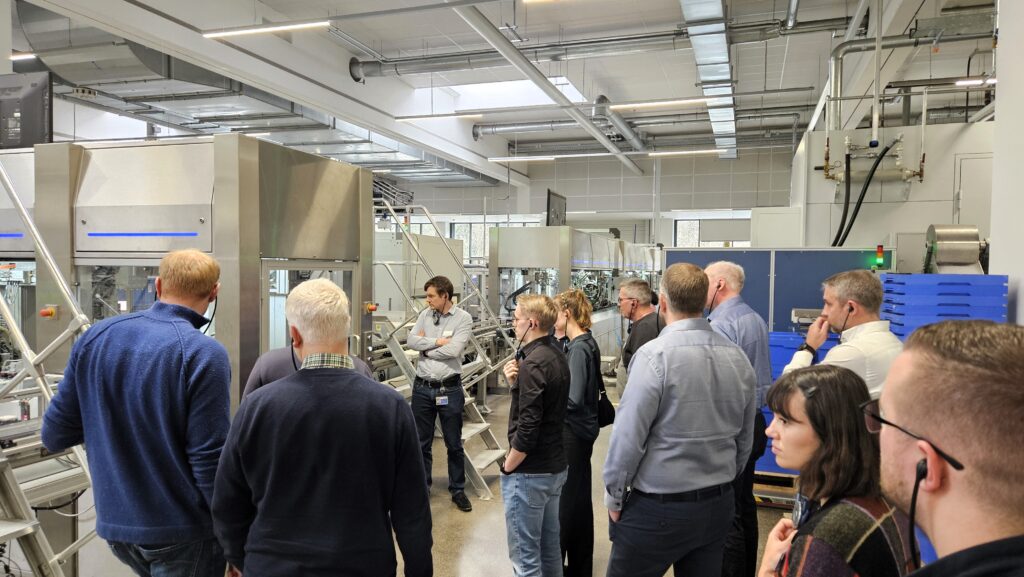

After these theoretical considerations, the participants split into two groups to take a short tour of the plant where the AI application is used.

The second part of the workshop delved deeper into the technical contexts on which JUNG’s AI approach is based.

The technical implementation was realized and supported by a team from IPS Engineers GmbH. Dr. Julian Schallow and David Lenze presented which software and which AI model are used at JUNG in order to solve the focused maintenance tasks even better. AI architecture in simple language and in fast motion: different data sources are bundled in one system. Data is modeled, features are constructed, read time windows and prediction windows are defined. The model is tested, trained, the results are analyzed and then the optimization begins. This happens continuously and continues to develop.

In the last part of the workshop, four smaller groups dealt with the questions of what benefits AI applications bring to their own company, what challenges and obstacles can be identified in AI projects, what solutions already exist and what the next steps on the topic of AI could look like in their own company.

In conclusion, it became clear that everyone is on the right track, but in different ways.

Increasing efficiency is the primary goal. It would be desirable to have an AI strategy that formulates where there is potential for AI applications in the company and how they can be used. In the hodgepodge of numerous individual use cases, there is sometimes a lack of a big picture that involves everyone involved and also keeps an eye on the necessary skills. Meaningful use cases need to be defined, budgets checked and projects implemented. The establishment of focus groups was seen as helpful.

Communication and exchange always help, not just at the snack after the workshop. We will therefore continue to provide the framework for this in the network. Our AI journey will continue. The next stage is a visit to WILO SE in Dortmund on April 8, 2025.

We would like to take this opportunity to thank the JUNG team for inviting us to Schalksmühle to kick off our AI journey. Many thanks to Dirk Wettlaufer and Dr.-Ing. André Hengstebeck for the willingness and presentation of the concrete example of the implementation of an AI application and Michael Schulte and Gunnar Szombach for the factory tours. Dr. Julian Schallow and David Lenze from IPS Engineers: Thank you for the expertly guided immersion into the technical background of the AI application and to all participants for their interest and enthusiasm.